Curtis 933/3D Series

The Curtis 933/3D series of battery controllers prolongs battery life and protects vehicle components from the effects of deep discharge in material handling and other battery-powered industrial vehicles. Battery 'fuel' gauge and controller includes lift lockout and adjustable reset and discharge settings. Available in single voltage and auto-ranging dual voltage models.

| Curtis Model Number | Voltage | Description | Part Number |

|---|---|---|---|

| 933/3D24 | 24 | Controller Only | A000009210 |

Curtis enGage™ II Series

The Curtis enGage II Series is a dual function, microprocessor based instrument that can be factory or user defined to monitor various functions including fuel, temperature, pressure, voltage, battery state of charge and maintenance/status.

| Curtis Model Number | Description | Voltage | Notes | Part Number |

|---|---|---|---|---|

| 3003R-67X-0001 | Maintenance Monitor/Hour Meter | 12-48 | Field programmable monitor allows users to program maintenance intervals, while displaying total hours. Does not include harness connector (A000016530). | A000016530 |

Curtis Unigage Series

The Curtis Unigage represents the new generation of Curtis 933/1 'Fuel' gauge and battery controller combination. In additon to the state of charge displayed on a multicolored ten-bar LED, the Unigage features an hour meter to monitor operating hours for the the truck. Sold as a replacement gauge for trucks already equipped with a Curtis Unigage.

| Curtis Model Number | Voltage | Description | Part Number |

|---|---|---|---|

| 933/1C243648J00100 | Unigage | 24/36/48 | A000007758 |

Unimeter Battery Monitor

Part Number: A000009439

The Unimeter features battery monitoring, an hour meter, and programmable maintenance scheduling.

Features:

- Adjustable for flooded or no-maintenance batteries

- Multi voltage - 12 to 48 volts DC

- "Zero drift technology" ensures Unimeter never requires recalibration, once set

- Two piece unit - Lexan Specific Instruction Display and Relay Box

- One 12" harness lead included

Battery Monitoring

The unit’s Specific Instruction Display indicates one of the following states of charge and the action required by the Operator>

- Green - Do Not Charge - The battery has sufficient charge to complete at least one full shift. Charging in this range can be destructive to the battery, wasting energy and reducing battery life.

- Yellow - Okay To Charge - The battery has sufficient capacity remaining to complete the present shift. Charging in this range is constructive charging and produces good lifetime battery capacity.

- Red - Must Charge - Operating the battery until the Must Charge instruction is illuminated produces maximum lifetime capacity, greatest number of shifts per charge, and lowest per ampere charging costs. Once the red light is illuminated, a warning beeps every 5 seconds, advising the Operator in advance that he/she has 10 minutes of lift operation before "lift lockout" engages.

- Battery Fault Indicator - The Battery Fault Indicator advises the Operator that a problem is developing with the battery. Problems detected could be: cell failure beginning, problem with inter cell connector, broken battery post, bad SB connector, etc.

Hour Meter

The hour meter can be programmed to record time in two different ways. It can record time based on the number of hours the ignition key is on, or it can record time based on run time (when the truck is actually being used). An LED displays the recorded number of hours. The Unimeter Programmer is used to specify the method of recording time.

Service

The service indicator illuminates when preventative maintenance is due to be completed. This is based on the number of hours specified when programming the Unimeter.

Programmable Maintenance Schedule

The Unimeter can be programmed with the number of hours before preventative maintenance is required for the vehicle. The number of hours is based on the method of recording time selected when programming the hour meter. When the preventative maintenance threshold is reached, the service indicator illuminates. An optional "lift lockout", which cannot be bypassed or defeated, can be programmed to ensure the required preventative maintenance does take place at some predetermined time after the service indicator illuminates. The Unimeter Programmer is used to program the Unimeter’s preventative maintenance settings.

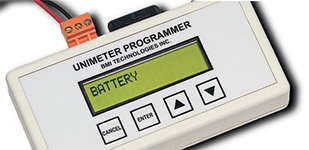

Unimeter Programmer

Part Number: A000025924

The hand-held Unimeter Programmer is used to field calibrate the Unimeter to your charging and preventative maintenance policies. Exclusive microprocessor technology eliminates guesswork and allows settings to be quickly and precisely raised or lowered, regardless of the battery’s state of charge, facility temperature, or load conditions.

The Unimeter Programmer is used to program:

- Battery voltage

- Specific gravity for the OK TO CHARGE and MUST CHARGE battery states

- Method of recording time

- Preventative maintenance schedule

- Lift lockout option