Curtis 802 Series

A completely solid-state battery discharge indicator and LCD hour meter without lift lockout in one 52mm instrument. Void of moving parts, this combination instrument is exceptionally reliable.

| Voltage | Description | Curtis Number | Part Number |

|---|---|---|---|

| 12 | BDI and hour meter | 802RB12BN | A000009215 |

Also Available

| Description | Part Number |

|---|---|

| Curtis Meterguard (polycarbonate lens) | A000009099 |

Curtis 803 Series

A completely solid-state battery discharge indicator and LCD hour meter with lift lockout in one 52mm instrument. Void of moving parts, this combination instrument is exceptionally reliable.

| Voltage | Description | Curtis Number | Part Number |

|---|---|---|---|

| 12 | BDI and hour meter | 803RB12BCJ | A000007748 |

Also Available

| Description | Part Number |

|---|---|

| 803 Series Installation Kit (wire harness) | A000009099 |

Curtis 900R Series

The model 900R is ideally suited for lead acid battery-powered vehicles that require a display function only.

| Voltage | Description | Curtis Number | Part Number |

|---|---|---|---|

| 12 | Battery Discharge Indicator | 900RB12BN | A000007752 |

Also Available

| Description | Part Number |

|---|---|

| Curtis Meterguard (polycarbonate lens) | A000009099 |

Curtis 906T Series

The 906T is an inexpensive, one-piece, easy-to-install battery fuel gauge. It is completely solid state and provides a reliable, accurate and easy-to-read display of battery charge state.

| Voltage | Description | Curtis Number | Part Number |

|---|---|---|---|

| 12 | Battery Capacity Indicator | 906T12BNMAO | A000007755 |

Curtis enGage™ II Series

The Curtis enGage II Series is a dual function, microprocessor based instrument that can be factory or user defined to monitor various functions including fuel, temperature, pressure, voltage, battery state of charge and maintenance/status.

| Curtis Model Number | Description | Voltage | Notes | Part Number |

|---|---|---|---|---|

| 3003R-67X-0001 | Maintenance Monitor/Hour Meter | 12-48 | Field programmable monitor allows users to program maintenance intervals, while displaying total hours. Does not include harness connector (A000016530). | A000016530 |

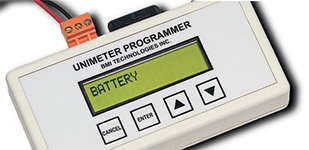

Unimeter Programmer

Part Number: A000025924

The hand-held Unimeter Programmer is used to field calibrate the Unimeter to your charging and preventative maintenance policies. Exclusive microprocessor technology eliminates guesswork and allows settings to be quickly and precisely raised or lowered, regardless of the battery’s state of charge, facility temperature, or load conditions.

The Unimeter Programmer is used to program the Unimeter’s>

- Battery voltage

- Specific gravity for the OK TO CHARGE and MUST CHARGE battery states

- Method of recording time

- Preventative maintenance schedule

- Lift lockout option